BERNOULLI FILTRATION SYSTEMS – RELIABLE FILTER SOLUTIONS

Bernoulli Systems produces reliable, self-cleaning water filters with an ingeniously simple design that ensures continuous, safe operation year after year. Bernoulli filter solutions are sustainable as they enable the use of water from natural sources such as sea, lake and river.

Bernoulli work for and with many customers to provide filter solutions which enables the use of water from natural sources such as sea, lake and river, in industrial cooling water systems and water treatment systems.

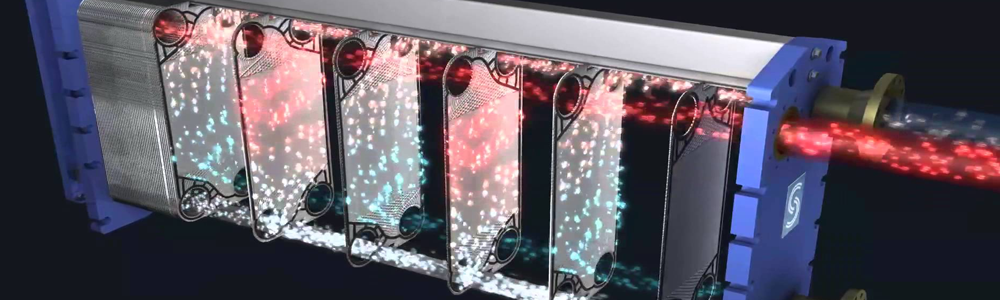

WORKING PRINCIPLE

Bernoulli System pioneered the application of the Bernoulli Principle, named after the Swiss scientist Daniel Bernoulli, to water filtration. The distinguishing feature of a Bernoulli Filter is a disc mounted on a pneumatic cylinder, which enables contactless cleaning of the filter. The cleaning sequence itself is automatic and continuous, requiring no manual intervention.

A. The flushing sequence is initiated by a timer setting or triggered by a differential pressure sensor before any blockage of the filter basket causes flow reduction.

B. In the pre-flushing stage, the flushing valve opens and larger particles are flushed out.

C. During the flushing sequence, a specially shaped flushing disc mounted on a pneumatic cylinder enters the filter basket and creates a gap between the disc and the filter basket.

- As the flow velocity increases locally around the disc, the static pressure is reduced in accordance with the Bernoulli Principle and the direction of the flow is reversed, thus releasing particles which are stuck to the surface of the filter basket.

- The released particles are led out from the filter through the flushing outlet

CENTRIFUGAL SEPARATORS

A centrifugal separator is not actually a filter since there is no screen element inside to filter out the particles. The separation is instead ensured by means of centrifugal force, and the separator’s efficiency is directly proportional to the specific density and size distribution of the particles. The centrifugal separator eliminates 98% of all particles with a specific gravity of 2.6-2.8 (such as sand) down to a size of 75 microns, provided that the pressure loss over the unit is minimum 0.3 bar.

Centrifugal separators should be installed downstream of the feed pump in order to ensure enough pressure during purging, and to overcome the pressure drop over the unit.

Advantages of centrifugal separators from Bernoulli System

- Separation occurs without any interruption to the flow

- Very little liquid is lost by purging

- No need for any consumable material

- Zero maintenance

- Separation efficiency

- Specific gravity table

Working principle

i) A liquid containing particles is fed tangentially into the cylindrical top of the centrifugal separator to create rotation. Passing through slots in the intake chamber, the flow velocity is further accelerated.

ii)The centrifugal force moves heavy particles to the sides of the barrel. They move downwards and accumulates in the collection chamber in the bottom of the separator.

iii)A deflector plate, located in the top of the collection chamber, changes the direction of flow.

iv)Solid-free liquid moves upwards inside the vortex and exits via the separator’s top outlet.

v)The separated solids are either periodically or continuously purged from the collection chamber.

Do review our animations

- Bernoulli Centrifugal Separator – NEW

https://bernoulli.se/wp-content/uploads/2021/05/Bernoulli-Cyclone-Separators.mp4

- The Bernoulli Filter – Primary timer based flushing

https://bernoulli.se/wp-content/uploads/2020/09/Cleaning_Principle.mp4

- The Bernoulli Filter – Dp-guard, over riding flushing generated by the local dirt controller

https://bernoulli.se/wp-content/uploads/2020/09/DP_Guard.mp4

Link to Bernoulli : www.bernoulli.se